UNLOCKING THE VAST POTENTIAL OF THE LITHIUM METAL BATTERY

PURE LITHIUM’S NEXT GENERATION BATTERY

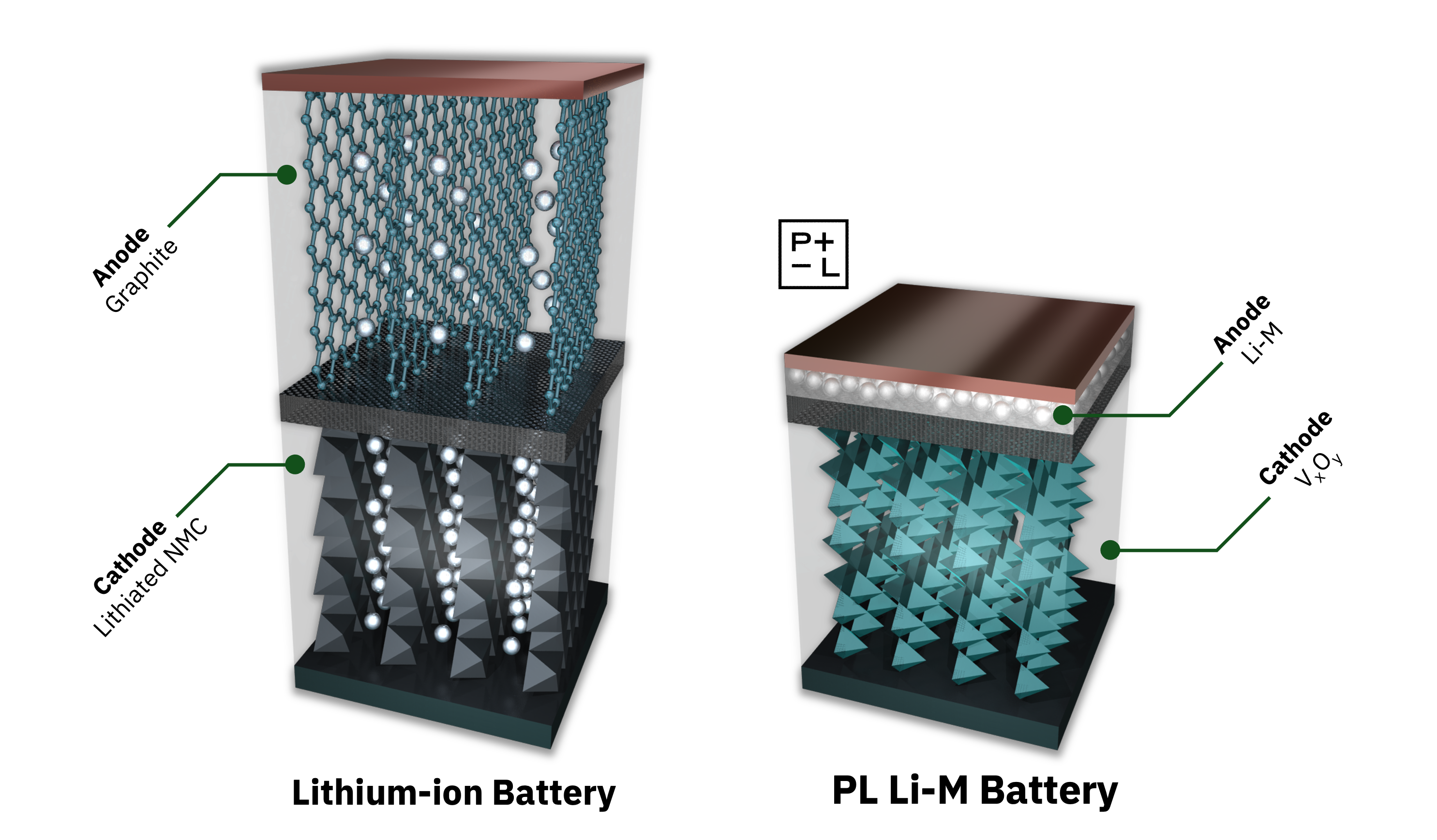

Pure Lithium’s proprietary Lithium Metal Advanced Anode is paired with two different cathodes to create the next generation of lithium batteries.

The Advanced Anode enables longer battery lifespan, energy density, and safety.

LITHIUM FLP

lithium vanadium

Gen-1 Li-LFP battery utilitizes a Lithium Iron Phosphate cathode.

This pairing results in:

$29/kWh on a materials level

6,000+ cycles of cycle life

300 Wh/Kg of energy density

Gen-2 LVO battery utilitizes a Vanadium Oxide cathode.

This pairing results in:

$29/kWh on a materials level

1,000+ cycles of cycle life

425 Wh/Kg of energy density

Simply put, our batteries outperform market leading technologies on energy density, lifespan, and cost. Furthermore, our LVO battery remains stable up to 1800C which provides a dramatically safer thermal profile.

robust Intellectual Property

Pure Lithium shares a joint patent application with battery pioneer Sir M. Stanley Whittingham. Professor Whittingham won the 2019 Nobel Prize in Chemistry for the invention of the lithium-ion battery.

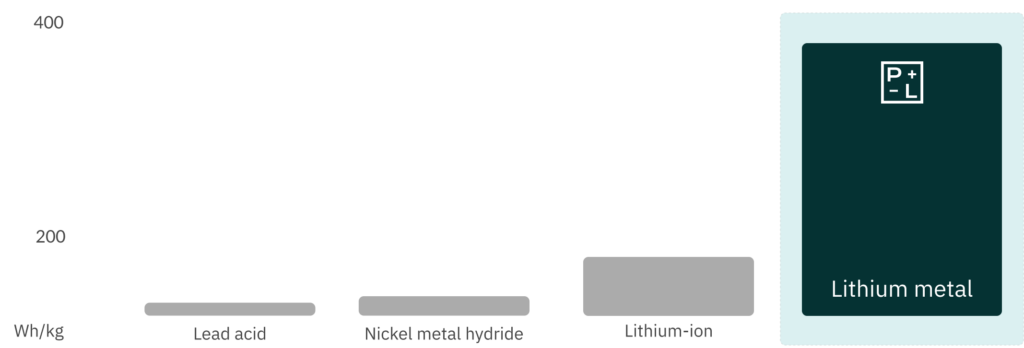

lithium metal vs lithium ion

The future of energy storage

Lithium metal offers about 10 times the capacity of a lithium-ion graphite anode which is needed to meet the growing storage demands.

Unable to meet the growing energy storage demand

Today’s lithium-ion batteries were created over four decades ago and were never meant to meet the world’s energy storage demands. Lithium metal provides a higher step change in energy density.

a STEP CHANGE IN ENERGY DENSITY

Only two batteries in our lifetime have been commercialized to gigawatt-hour scale: lead-acid and lithium ion.

Lithium metal is next and will replace the lithium ion battery.

BRINE TO BATTERY™ REVOLUTIONIZES PRODUCTION

Our Brine to Battery™ technology revolutionizes battery production by combining lithium extraction and anode production into a single, vertically integrated process. This enables fast, inexpensive, safer, and more sustainable manufacturing of battery-ready lithium metal anodes at a commercially viable cost of approximately $15/kWh.

Using widely available lithium brine, we electrodeposit highly pure lithium metal directly onto a copper substrate, forming a full battery anode in a single step, thus bypassing traditional lithium compound production and eliminating multiple costly and energy-intensive processing stages.

Pure Lithium is the only company to combine lithium metal extraction and anode production in this way, unlocking a fundamentally new supply chain model that delivers lower cost, faster time-to-production, and a greener pathway to large-scale lithium-metal batteries.

Lithium Metal Electrodeposition

Pure Lithium’s proprietary polymer membrane conducts only lithium and protects the lithium metal anode from water. Our process deposits ultra-thin, 99.9% pure lithium metal onto a substrate directly from brine. This is completely different than direct lithium extraction (DLE), which cannot produce lithium metal.